- English

- United States(USD $)

- Home

-

All products

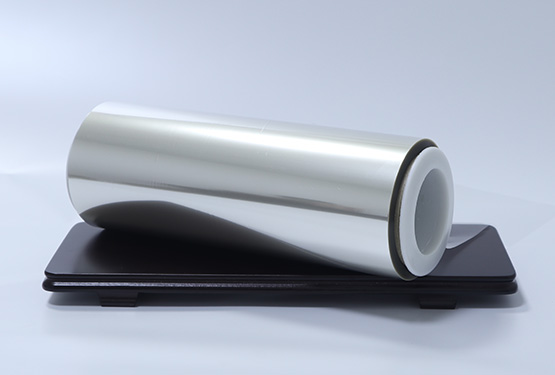

- Transparent High Barrier AlOx PET Film

- Vacuum Metallized PET Film

- Other Vacuum Metallized Plastic Film

- Dielectric metallized film

- Holographic Film

- Vacuum Semi-Metallized Film

- Copper Metallized PET film

- Color PET film

- Metallized PET film with precoating

- Metallized PET lamination film

- High performance Metallized PET film

- PEEK Film

- About

- Quality Control

- Contact

- FAQ

- News

Dielectric Film Plating

Product display

|

|

|

Technical Date

|

Testing Methods |

Standard Value |

Result |

Conclusion |

|

|

Apparence |

Film |

There should be no broken edges, flanging, scratches, wrinkles, severe bursts, holes, impurities, and Aluminium layer peeling off. |

Passed |

Qualified |

|

Sputtering point |

≤4 pcs/m2 |

Passed |

Qualified |

|

|

Connector |

The joints shall be neat, firm and smooth; the number of joints per roll shall not exceed one, and the length of each section shall not be less than 500m. |

Passed |

Qualified |

|

|

Film Roll End Face |

Unevenness ≤ 4mm |

Passed |

Qualified |

|

|

Film roll core |

Smooth surface, no bending, dent, or collapse |

Passed |

Qualified |

|

|

Size and deviation |

Thickness(µm) |

12 |

12.1 |

Qualified |

|

Thickness deviation(%) |

±10 |

0.8 |

Qualified |

|

|

Width deviation(mm) |

±2 |

0 |

Qualified |

|

|

Tensile Strength (MPa) |

MD |

≥170 |

208 |

Qualified |

|

TD |

≥170 |

212 |

Qualified |

|

|

Elongation at break (%) |

MD |

≥80 |

106 |

Qualified |

|

TD |

≥80 |

112 |

Qualified |

|

|

Heat Shrinkage (%) |

MD |

≤3.0 |

1.26 |

Qualified |

|

TD |

≤2.0 |

0.1 |

Qualified |

|

|

Alu.side Surface Tension(mN/m) |

≥38 |

54 |

Qualified |

|

|

Alu Adhesion |

1级 |

1级 |

Qualified |

|

|

Alu Layer Thickness(Ω/口) |

- |

78% |

Qualified |

|

|

Alu Layer Uniformity(%) |

±3 |

±2 |

Qualified |

|

|

Testing Judgement |

Qualified |

|||

Important Tips:

1.The data and ,information above are obtained from our company's tests, for customers' reference of sample or the product usage;

2.The final performance of the product is related to the composite process,and improper use will cause destructive damage to the product;

3.For other special requirements,it is better to contact with our technical department for more details,so that the products are more suitable for customers.

Application

Widely used in cosmetic packaging, decorative materials etc